Introduction

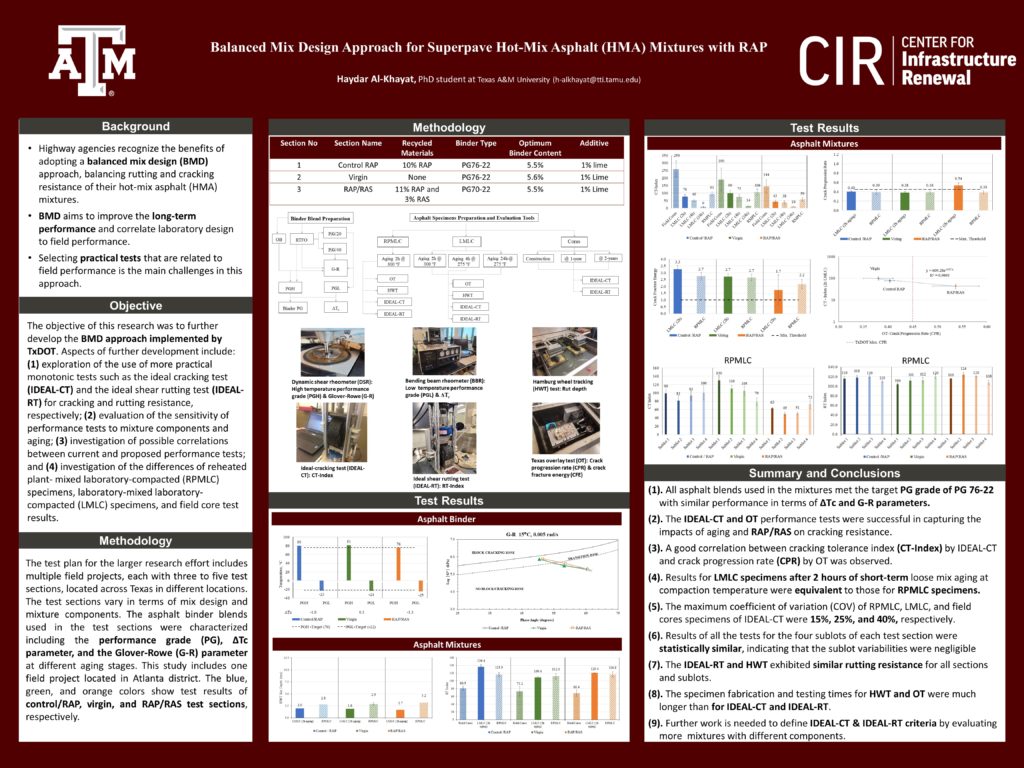

Highway agencies recognize the benefits of adopting a balanced mix design (BMD) approach, balancing rutting and cracking resistance of their hot-mix asphalt (HMA) mixtures. This approach aims to improve the long-term performance and correlate laboratory design to field performance with a focus on the quality of the component materials and corresponding mixture, as compared to pure volumetric mix design that is limited to assessing the quantity of materials. Like many other states, the Texas Department of Transportation (TxDOT) in interested in further developing their current BMD specification and using more recycled materials. Currently, TxDOT is using the Overlay (OT) and the Hamburg Wheel Tracking (HWT) repeated load tests to measure the cracking and rutting resistance, respectively, to verify mix designs proportioned by the Superpave volumetric method. Aspects of further development include: (1) exploration of the use of more practical monotonic tests such as the ideal cracking test (IDEAL-CT) and the ideal shear rutting test (IDEAL-RT) for cracking and rutting resistance, respectively; (2) evaluation of the sensitivity of performance tests to mixture components and aging; (3) investigation of possible correlations between current and proposed performance tests; and (4) investigation of the differences of reheated plant- mixed laboratory-compacted (RPMLC) specimens, laboratory-mixed laboratory-compacted (LMLC) specimens, and field core test results. The test plan for the larger research effort includes multiple field projects, each with three to five test sections, located across Texas in different locations. The asphalt binder blends used in the test sections were characterized including the performance grade (PG), ΔTc parameter, and the Glover-Rowe (G-R) parameter at different aging stages. This study includes one field project with three test sections (control/RAP, virgin, and RAP/RAS), each with four sublots. Results for LMLC specimens after 2 hours of short-term loose mix aging at compaction temperature were equivalent to those for RPMLC specimens. The maximum coefficient of variation (COV) of RPMLC, LMLC, and field cores specimens were 15%, 25%, and 40%, respectively. A good correlation between cracking tolerance index (CT-Index) by IDEAL-CT and OT parameters was observed. The IDEAL-RT and HWT exhibited similar rutting resistance for all sections and sublots. The specimen fabrication and testing times for HWT and OT were longer than for IDEAL-CT and IDEAL-RT. All asphalt blends used in the mixtures met the target PG grade of PG 76-22 with similar performance in terms of ΔTc and G-R parameters. Finally, to adopt the proposed tests and develop new criteria, more mixtures with different components need to be evaluated.

that is limited to assessing the quantity of materials. Like many other states, the Texas Department of Transportation (TxDOT) in interested in further developing their current BMD specification and using more recycled materials. Currently, TxDOT is using the Overlay (OT) and the Hamburg Wheel Tracking (HWT) repeated load tests to measure the cracking and rutting resistance, respectively, to verify mix designs proportioned by the Superpave volumetric method. Aspects of further development include: (1) exploration of the use of more practical monotonic tests such as the ideal cracking test (IDEAL-CT) and the ideal shear rutting test (IDEAL-RT) for cracking and rutting resistance, respectively; (2) evaluation of the sensitivity of performance tests to mixture components and aging; (3) investigation of possible correlations between current and proposed performance tests; and (4) investigation of the differences of reheated plant- mixed laboratory-compacted (RPMLC) specimens, laboratory-mixed laboratory-compacted (LMLC) specimens, and field core test results. The test plan for the larger research effort includes multiple field projects, each with three to five test sections, located across Texas in different locations. The asphalt binder blends used in the test sections were characterized including the performance grade (PG), ΔTc parameter, and the Glover-Rowe (G-R) parameter at different aging stages. This study includes one field project with three test sections (control/RAP, virgin, and RAP/RAS), each with four sublots. Results for LMLC specimens after 2 hours of short-term loose mix aging at compaction temperature were equivalent to those for RPMLC specimens. The maximum coefficient of variation (COV) of RPMLC, LMLC, and field cores specimens were 15%, 25%, and 40%, respectively. A good correlation between cracking tolerance index (CT-Index) by IDEAL-CT and OT parameters was observed. The IDEAL-RT and HWT exhibited similar rutting resistance for all sections and sublots. The specimen fabrication and testing times for HWT and OT were longer than for IDEAL-CT and IDEAL-RT. All asphalt blends used in the mixtures met the target PG grade of PG 76-22 with similar performance in terms of ΔTc and G-R parameters. Finally, to adopt the proposed tests and develop new criteria, more mixtures with different components need to be evaluated.