Summary

This lab houses research on all things concrete – developing innovative and sustainable construction materials; alternative cementitious materials; concrete durability (especially ASR and freeze-thaw) with new and innovative approaches; developing performance-based approaches to formulate concrete mixes for different sustainable applications; the recycling and reuse of waste and marginal materials; nanotechnology; high-performance cement; innovative concrete curing practices; innovative approaches to studying concrete permeability and creep; durability-based specifications for high-performance concrete; innovative concrete pavement design; concrete microstructure; and material science aspects of cement, aggregate and concrete.

Research

- Performance-based approach to designing alkali-silica reaction (ASR)-resistant concrete using newly developed innovative test methods and innovative approach for effective utilization of reclaimed, off-spec ashes and alternative SCMs to prevent ASR.

- Potential to increase the service life of existing infrastructure by offering corrective measures to common distresses (such as cracking, spalling, curling, alkali-silica reactions, and sulfate attacks) that affect our pavements and bridges.

- Developing performance specification meeting the durability requirements for High Performance Concrete (HPC) and developing non-proprietary ultra-high performance concrete (UHPC) mixes using locally available materials.

- Provide recommendations for new infrastructure including non-invasive and rapid quality control and quality assurance technologies, maintaining proper levels of curing and skid resistance, and reducing noise.

- Potential innovative areas of research include: (i) low cracking concrete for overlays, (ii) application of nanotechnology to develop multifunctional (e.g., self-healing, self-cleaning, conductive) materials, (iii) developing improved opportunities for recycled materials, (iv) developing rapid, high-performance Portland Cement Concrete (PCC) pavement repair materials, (v) a curing monitoring system to verify the curing effectiveness of the curing compounds, and (vi) innovative NDT techniques for detecting and monitoring concrete distress.

Capabilities

- Innovative way to estimate pore solution alkalinity (PSA) of concrete and aggregate threshold alkali loading (TAL) and perform fly ash optimization using Volumetric change-measuring devices (VCMDs) and accelerated concrete cylinder tests (ACCTs) for formulation of ASR-resistant mixtures.

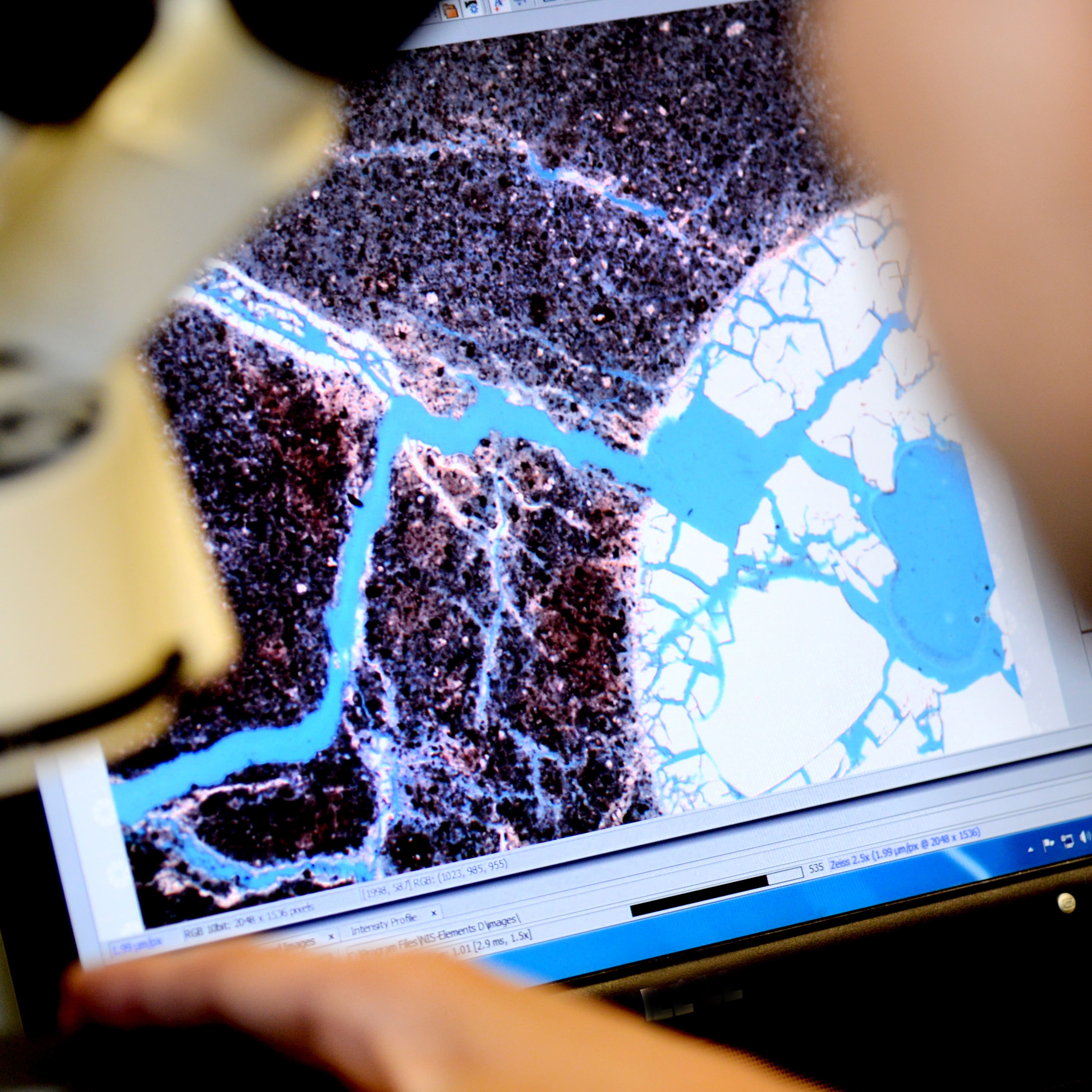

- Micro- and nano-structural characterization of cement paste, mortar, and concrete using advanced micro- and nano-analytical techniques.

- Fundamental material science research, including the application of nanotechnology to develop novel materials and new materials.

- Microstructural Observation:

- Petrographic observations (ASTM C295 and 856) using light microscopes and point counter for aggregate, clinker, cement, mortar, and concrete based on both thin section and polished specimens.

- X-ray microscope (XRM) for non-destructive 3D observations of micro-structures in concrete, mortar, asphalt, aggregate, soil and other construction materials.

- Materials Testing:

- X-ray fluorescence (XRF) for chemical compositions of samples including liquid or solid.

- X-ray diffraction (XRD) for (i) identification and quantification of crystalline phases, and (ii) determination of amorphous contents in cement, fly ashes, soil and aggregate and other construction materials.

- Fourier transform infrared analysis (FT-IR) for a molecular fingerprint of the sample.

- Laser particle-size analyzer (PSA) for measurement of the particle size between 10 nanometers and 5 millimeters using either dry powder or liquid.

- MTS 815 Rock and concrete test system for uniaxial and triaxial tests – compressive strength (ASTM C39), splitting tensile strength (ASTM C496), elastic modulus (ASTM C469), flexural strength (ASTM C78) and flexural toughness (ASTM C1018).

- Abrasion test machine for testing the relative abrasion resistance of concrete surface (ASTM C779 and C994).

- Resistivity meters for non-destructive assessment of permeability (ASTM C 1760/AASHTO TP 95) and formation factor based diffusion coefficients as well as apparent chloride diffusion (ASTM C1556) and service life prediction.

- Single ring test (ASTM C 1581) for evaluation of shrinkage cracking.

- Rapid chloride permeability test (RCPT) for measurement of the chloride permeability of in-place concrete (ASTM C1202).

- Freeze thaw chamber (ASTM C666) and other climate chambers for the flexibility to simulate a broad range of environmental conditions (a temperature range of -25°C to 70°C and humidity range from 20% to 95%).

- A curing monitoring system for measurement of ambient relative humidity (RH) and the RH at the concrete surface, and inside the concrete.

See us in action

Lab Supervisors:

Dr. Anol Mukhopadhyay

Senior Research Scientist and Program Manager, Adjunct Professor, Civil Engineering, Director, Concrete Innovation Lab, CIR

[email protected]

979-458-4618

Dr. Zach Grasley

Department Head and Professor, Civil Engineering, Texas A&M

[email protected]

979-317-1201