Summary

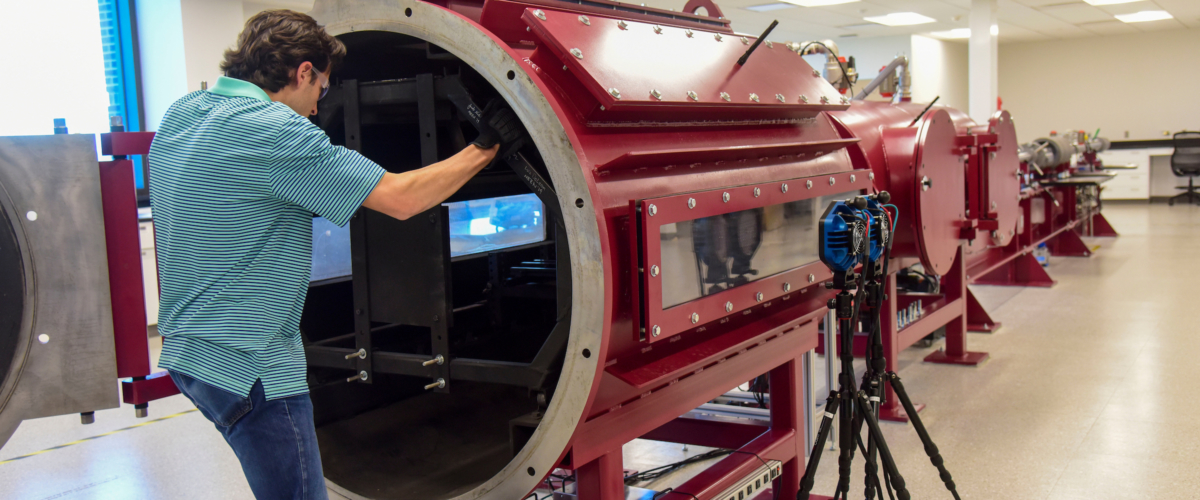

The state-of-the-art Hypervelocity Impact Lab is aimed at enabling unique high-rate materials characterization and multiscale numerical model development and implementation. A state-of-the-art two-stage light gas gun (2SLGG), capable of launching 2-10 mm diameter projectiles at velocities in the range of 2-8 km/s (4400-18,000 miles/hour), is the focal point of this lab. It will provide a test bed for the development and tailoring of novel layered structures comprised of polymers, composites, metals, ceramics, soft materials, gels and geomaterials to mitigate hypervelocity impacts.

Research

- Tailoring of high strain rate materials of extreme environments.

- Conduct state-of-the-art experiments necessary to characterize ultra-high rate materials behavior.

- Quantification of the dynamic high velocity impact response of different materials over a broad range of impact velocities and target geometries.

- Characterization and quantification of damage due to hypervelocity impact as a function of target material, target geometry, and impact velocity.

- Develop and validate computationally-efficient, physics-based, multiscale materials models for predicting damage and failure.

Capabilities

- Two-stage Light Gas Gun

- Pump Tube: 8’ long and 1.75” diameter

- Flight Tube: 12’ long and 0.5” diameter

- Target Tank: 6’ long and 46” diameter

- Velocity range: 2-8 km/s

- High and low temperature testing capability

- Instrumentation

- Ultra-high-speed cameras (10 Mfps)

- Flash X-rays (450 kV)

- Diagnostic Techniques

- Schlieren Imaging (1 Mfps)

- Dualscope Imaging (1 Mfps)

- Ultra-high-rate spectroscopy (1 Mfps)

- 2D particle tracking of fragments and projectiles.

- Ability to launch simultaneously launched distributed particles (SDLPs)

- Sizes .5 - 2.0 mm

- Velocity Range: 2 - 8 km/s

- Single Stage Gas Gun

- Utilizes existing flight tube and target tank

- Velocity Range: 100 - 1500 m/s”